What Is A Pull System

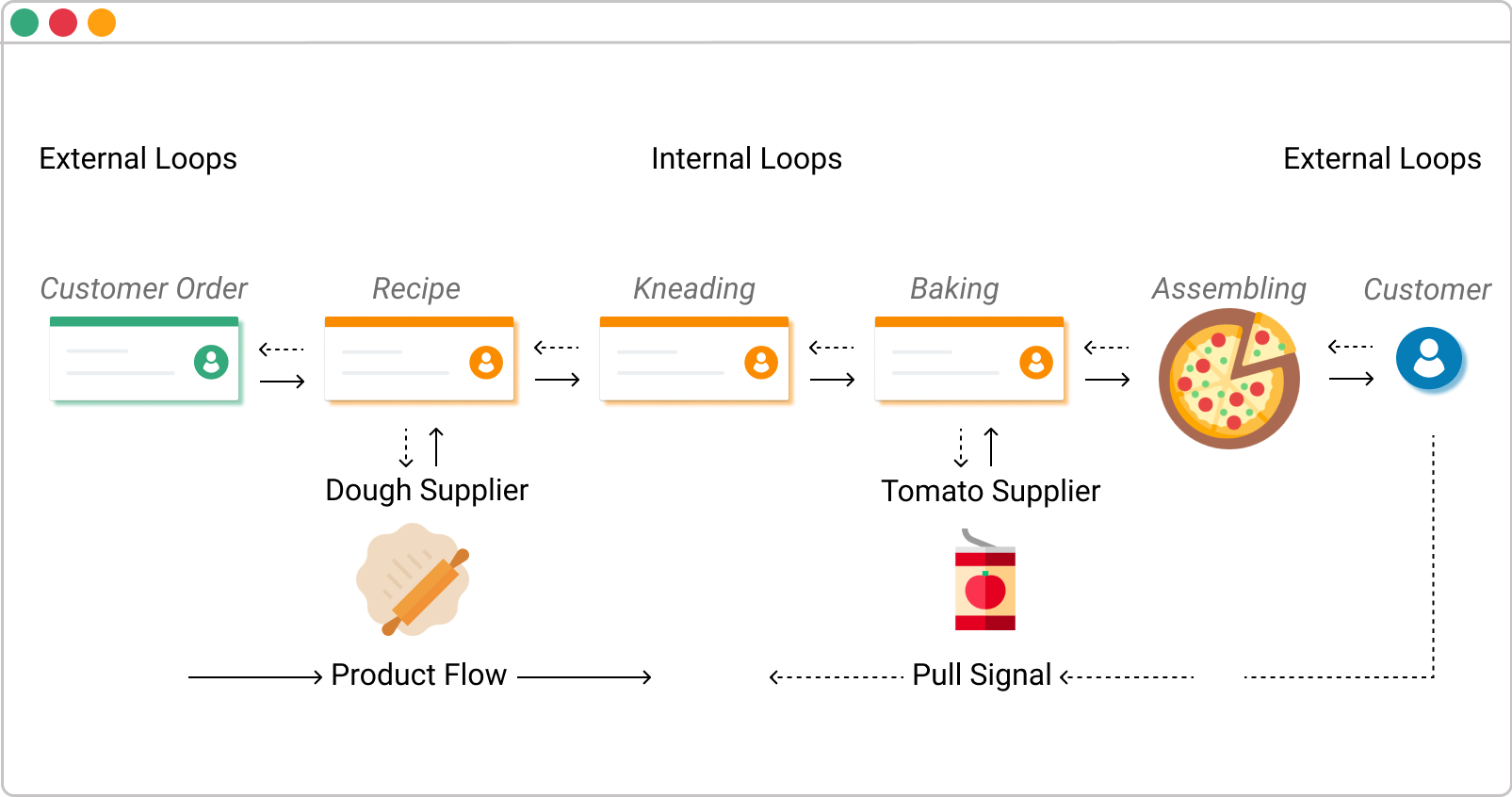

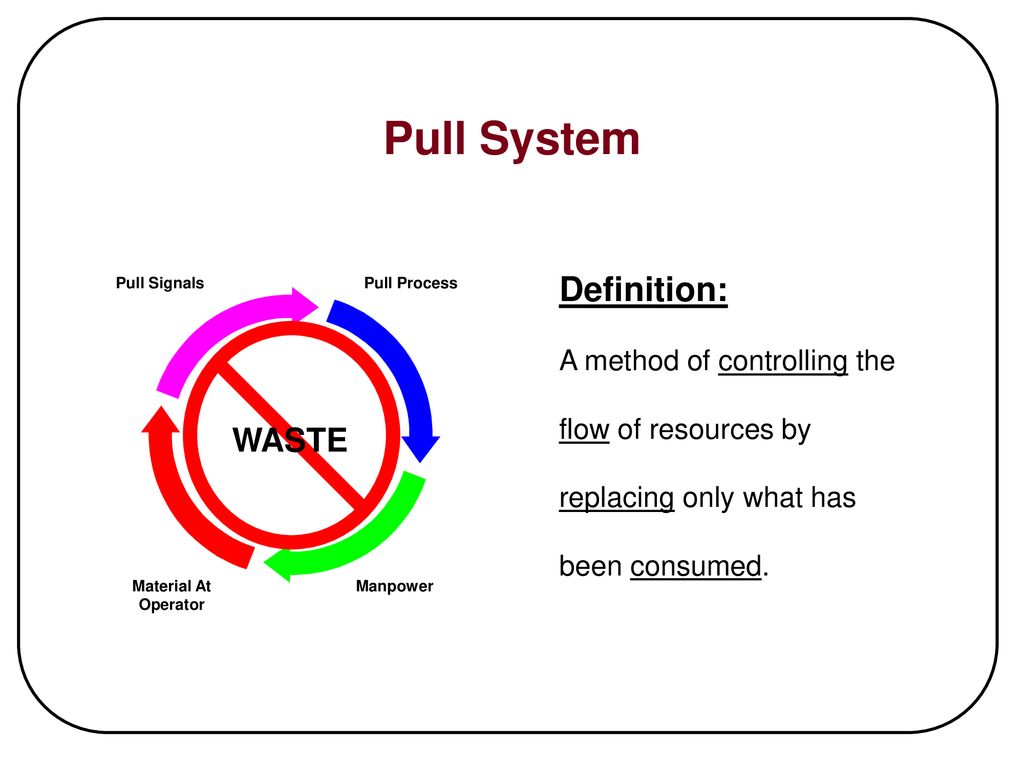

What is a pull system. This allows you to reduce overhead and optimize storage costs. The Pull System is a lean manufacturing method that uses the Just-in-Time strategy of not producing goods until an order is received. A pull system is a Lean Six Sigma method used to stabilize a process flow into a predictable work control system.

A pull system is a lean manufacturing strategy used to reduce waste in the production process. Pull Systems What Is a Pull System. Instead of forecasting demand.

Pull inventory management systems aim to keep a minimal amount of stock on hand. When working on a project team a pull system can be used to help teams complete work more efficiently as a part of a workflow. Pull production strives to eliminate overproduction and is one of the three major components of a complete just-in-time production system.

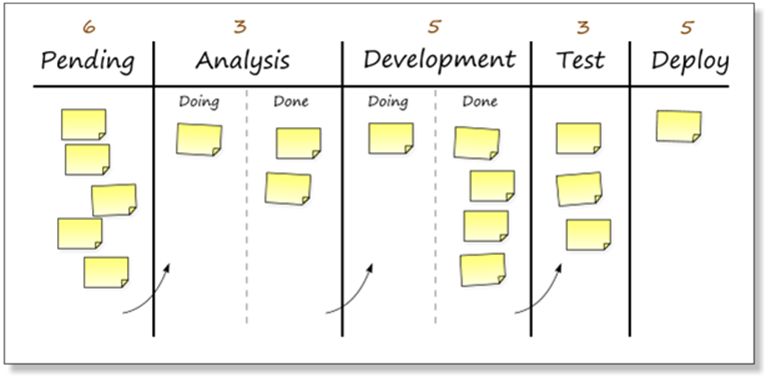

Applying a pull system allows you to start new work only when there is customer demand for it. Used with a kanban board a kanban pull system is a visual productivity tool that allows workers to pull their next tasks from a list of in-demand objectives. In the process of getting the hang of Lean management you will learn that establishing a pull system of work is among the most important prerequisites to achieving optimal process efficiency.

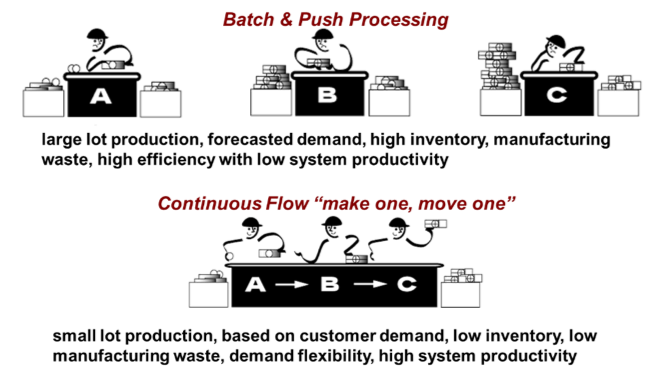

Having a lean and dynamic ordering plan helps you minimize the risk of unsold wasted product. This works by ordering small amounts of inventory in response to customer demand rather than forecasting and placing bulk orders in advance. A Pull System is a scheduling system that relies on pulling resources from one area to another only when those resources are actually required which can help avoid excess inventory and waste.

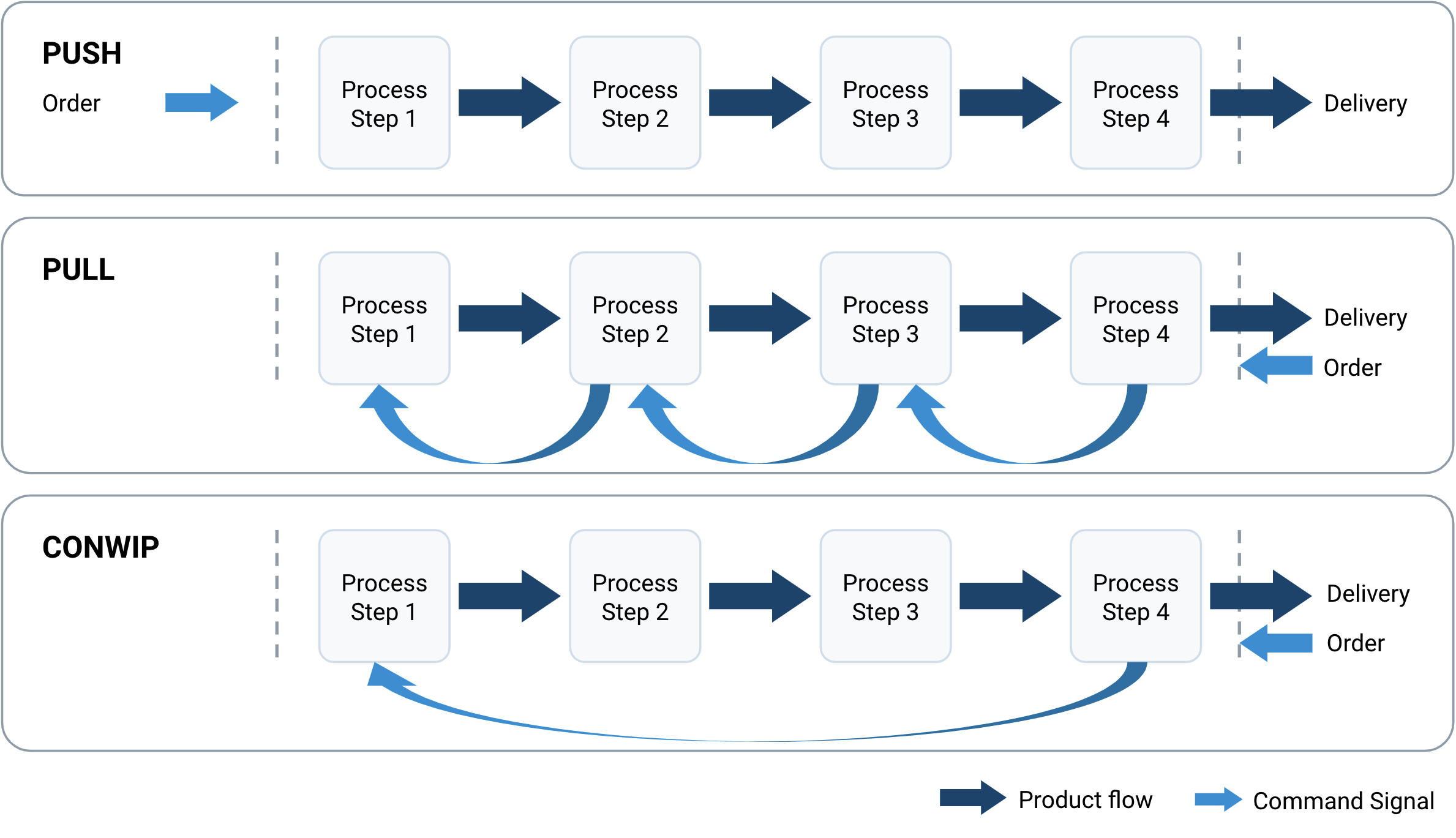

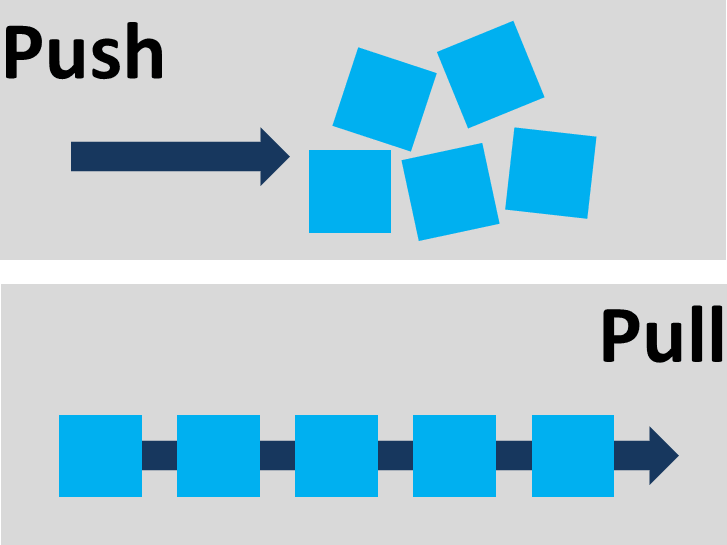

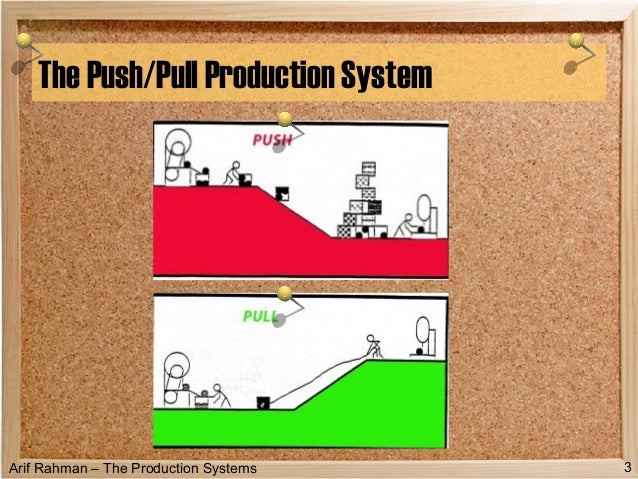

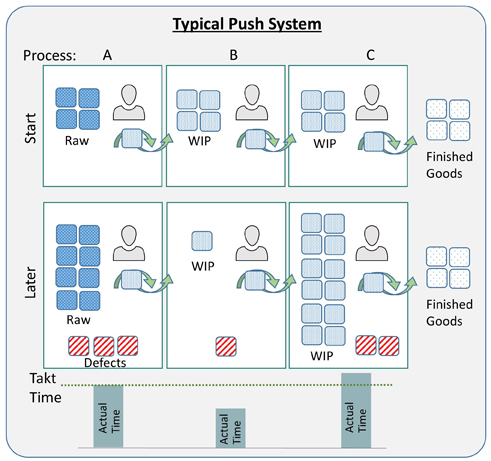

Work methods that use pull systems allow people to manage the flow of resources by limiting work in. A pull system is contrasted with a typical push system that is common with mass production. What is a pull system.

Since you cannot produce before the parts arrive the delivery times are part of the overall lead-time for the customer order. Search Across Hundreds of Distributors to Compare Prices Inventory and Save.

Pull production strives to eliminate overproduction and is one of the three major components of a complete just-in-time production system.

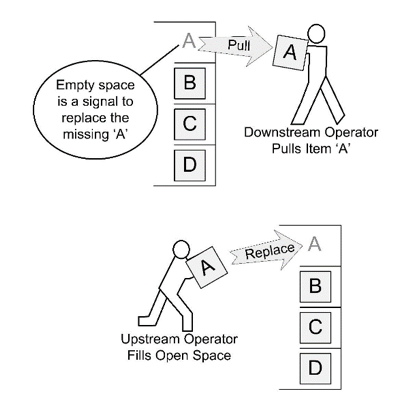

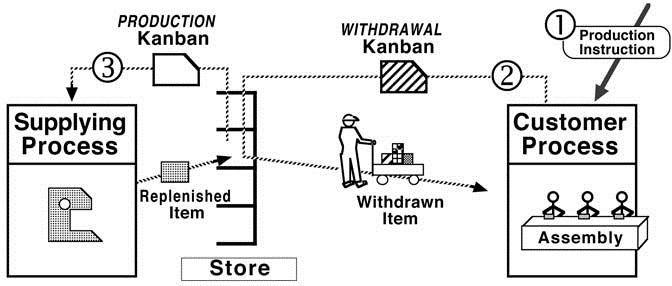

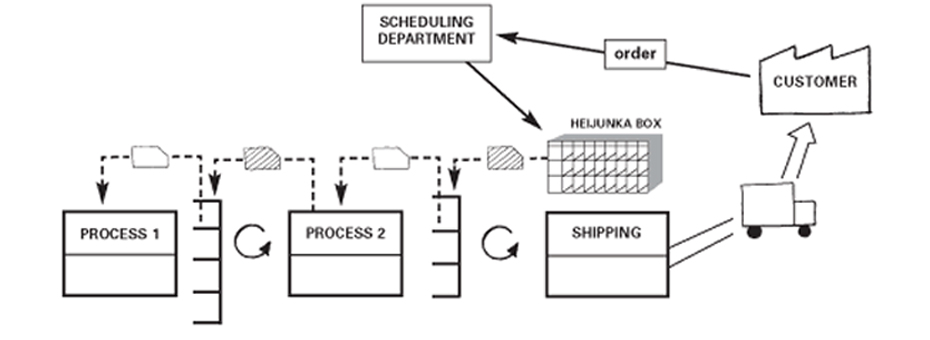

Work methods that use pull systems allow people to manage the flow of resources by limiting work in. Pull is a powerful concept that will allow you to take control of your workflow and deliver value to your customers precisely when it counts. Used with a kanban board a kanban pull system is a visual productivity tool that allows workers to pull their next tasks from a list of in-demand objectives. A pull system is a Lean technique for reducing the waste of any production process. A Pull System is a scheduling system that relies on pulling resources from one area to another only when those resources are actually required which can help avoid excess inventory and waste. A method of production control in which downstream activities signal their needs to upstream activities. Kanban is all about. The opposite of pull is push and understanding both terms will help every leader make better operational strategic decisions for their business. Having a lean and dynamic ordering plan helps you minimize the risk of unsold wasted product.

Kanban is all about. Since you cannot produce before the parts arrive the delivery times are part of the overall lead-time for the customer order. A pull system is a Lean Six Sigma method used to stabilize a process flow into a predictable work control system. Pull is a powerful concept that will allow you to take control of your workflow and deliver value to your customers precisely when it counts. The Kanban pull system is a lean management techniques focused on optimizing the workflow according to demand. Search Across Hundreds of Distributors to Compare Prices Inventory and Save. Push Pull System Videos.

Post a Comment for "What Is A Pull System"